Robotics plays a crucial role in food and beverage manufacturing, offering capabilities that were previously unimaginable. Robotic arms can perform repetitive tasks with precision and accuracy, increasing production efficiency and reducing the risk of human error. They can also handle delicate and fragile ingredients without damaging them, ensuring the highest quality standards are met.

Artificial intelligence is another game-changer in the industry. AI-powered software systems can analyze vast amounts of data in real-time, enabling manufacturers to optimize processes, predict demand, and improve inventory management. AI can also be used to develop new recipes and flavors, creating innovative products that cater to changing consumer preferences.

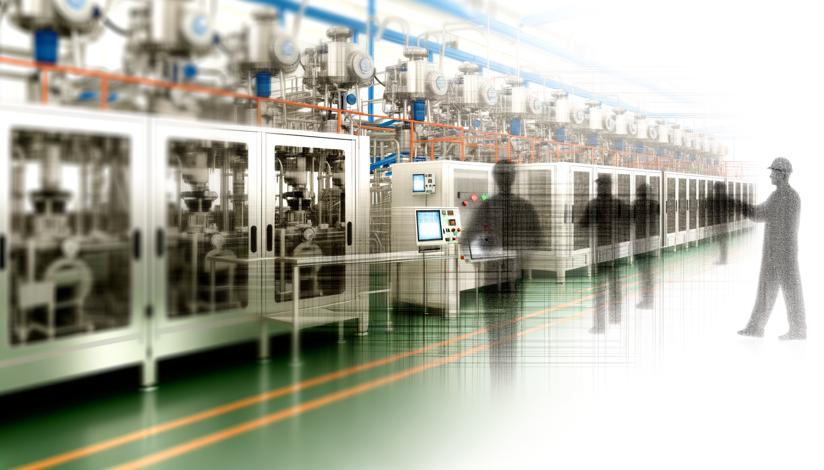

Industry 4.0, also known as the fourth industrial revolution, is characterized by the integration of digital technologies into manufacturing processes. It encompasses technologies such as the Internet of Things (IoT), cloud computing, and big data analytics. By connecting machines, sensors, and devices, manufacturers can create a fully interconnected and automated production environment. This enables real-time monitoring, predictive maintenance, and remote control of manufacturing operations, resulting in improved productivity and reduced downtime.

Smart manufacturing takes Industry 4.0 to the next level by leveraging advanced technologies to create highly efficient and flexible production systems. With smart manufacturing, manufacturers can automate the entire production process from raw material sourcing to packaging and distribution. This not only improves efficiency but also allows for greater customization and personalization of products to meet individual customer needs.

In conclusion, the future of food and beverage manufacturing is bright with the integration of robotics, artificial intelligence, industry 4.0, and smart manufacturing. These technologies offer numerous benefits, including increased productivity, improved quality control, reduced costs, and enhanced customization. However, it is important for manufacturers to carefully analyze their specific needs and invest in the right technology solutions to fully capitalize on these opportunities.

Overall, the future of food and beverage manufacturing is exciting and full of potential. With the right mix of technology and automation, manufacturers can stay ahead of the competition and meet the ever-changing demands of consumers.

Increased production efficiency

Improved quality control

Customization and personalization

Initial cost of implementation

Need for skilled workforce

Potential job displacement

-

https://www.foodprocessing.com

-

https://www.manufacturingtomorrow.com

-

https://www.forbes.com